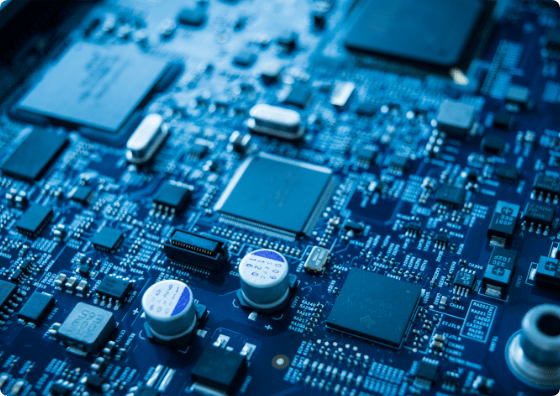

TURN-KEY PCB ASSEMBLY SERVICES

Sit back and relax, we'll do it all for you!

All you have to do is provide the design files, we will source the PCBs, the board level components (parts) and the SMT stencil. We will assemble your printed circuit boards in our state-of-the-art facility and ship you the assembled PCBs with any remaining parts.

Learn more about our PCB fabrication services and electronic components sourcing.

Though most customers prefer our turnkey PCB assembly services we also offer consignment services.