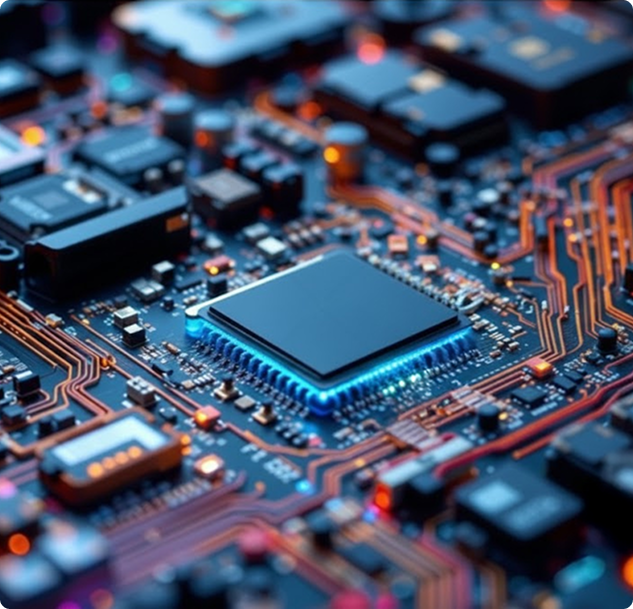

Integrated PCB

Assembly Services

Our integrated services streamline your entire production cycle by consolidating PCB fabrication, component procurement, SMT and through-hole assembly, conformal coating, testing, and box build assembly.

Benefits of Integrated PCB Assembly Services

Single Point of Responsibility

Shorter Lead Times

Optimized Supply Chain Management

Greater Flexibility and Scalability

Lower Total Cost

Enhanced Quality and Consistency

Better Traceability

Reduced Risk

Get an Instant Quote