PCB Assembly Explained

PCB Assembly is the process of building a Printed Circuit Board (PCB). That means placing the components on their designated locations and soldering them to the board. This creates both mechanical and electrical connections between the PCB and the components.

There are multiple methods to do PCB assembly. Hand soldering is the most basic one. It consists of hand-placing the components to then using solder wire and a soldering iron. This tedious manual process is only viable for very small batches. For larger quantities, automation is required.

Surface Mount vs Through Hole Assembly

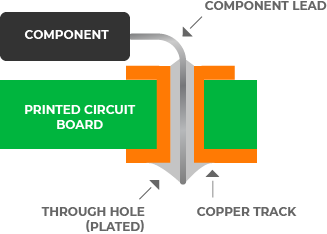

There are two mounting technologies in PCB Assembly. The first developed technology was through-hole assembly. It works by inserting the component’s pins or leads into copper-plated holes that pierce through the PCB. On the other side of the board, solder is applied and molten with heat to form a junction.

Through hole was the dominant technology in the early days of the PCB industry. Over time, with the increasing need for miniaturization, surface mount technology was developed.

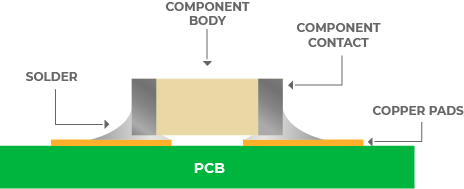

Surface mount consists of placing components onto the surface of the PCB. The component package has flat legs, pads or solder balls. Previously, solder paste (a mixture of small solder particles and flux) is applied over the PCB pads, so the component’s pins sit over a layer solder paste. This eliminates the need of holes on the PCB. Finally, the board and components are heated up, melting the solder to form a junction in a process called reflow.

Surface mount devices are typically smaller than through hole components, in part because of the absence of leads, allowing more compact designs with the same functionality and capability.

Materials and Equipment

For automated PCB assembly, specialized equipment is required. To operate the machines, staff with special training is needed. This means a considerable initial investment, but the resulting streamlined process is capable of building a large number of boards in relatively short time. The most important equipment units that you will find in an automated assembly line are:

For Surface Mount Assembly

- Stencil printer: A machine that applies solder paste using a squeegee blade and a stencil. Apertures on the stencil allow the solder paste to flow only through the open areas, which are aligned with the surface mount pads on the PCB.

- Pick and Place machine: Similar to a robot equipped with a visual system and a pneumatic header that picks components up from reels or trays and places them with great precision on their location of the PCB.

- Reflow Oven: A type of oven used to melt (reflow) the solder by following a specified temperature curve (solder profile). Inside the oven, the boards and components are passed through different stages, such as pre-heat, reflow and cool-down in a controlled manner to ensure forming proper junctions without damage.

For Through Hole Assembly:

- Wave solder machine: Consists of a heated pot of molten solder that creates a standing wave. This solder wave makes contact with the circuit board. As it passes, components become soldered to the board.

- Selective solder machine: This machine works by automatically applying molten solder only over specific regions of a circuit board, avoiding damage to sensitive components.

Optical Inspection

Once the components have been mounted and soldered onto the PCBs, the manufacturer needs to verify the result of the process. Quality assurance is performed using visual inspection tools. As with the mounting technologies, they can be manual or automatic.

An Automated Optical Inspection (AOI) machine is an optical device used to check and analyze assembled PCBs to detect potential defects and errors occurred during assembly by combining image sensors and software that detects small details that the human eye is prone to omit.

At PCB Assembly Express we specialize in both Surface Mount and Trough Hole assembly using state-of-the-art equipment. You can get an instant quote from our website or email a request for a quote to support@pcbassemblyexpress.com or simply call at 800-651-7250 to talk to a friendly customer service representative.

LEAVE A REPLY