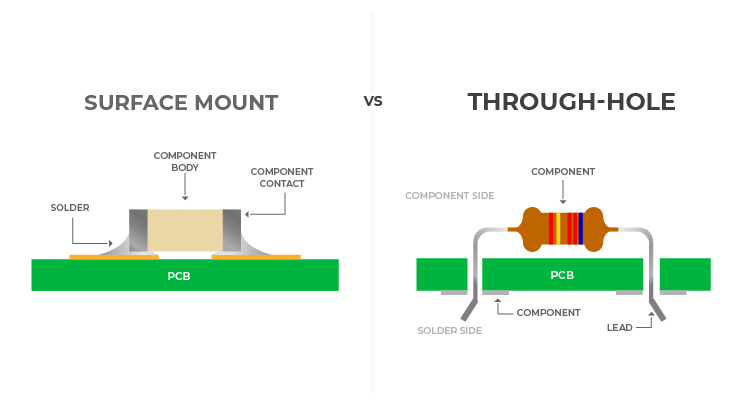

PCB Assembly – SMT vs Through-Hole

What is Surface Mount technology

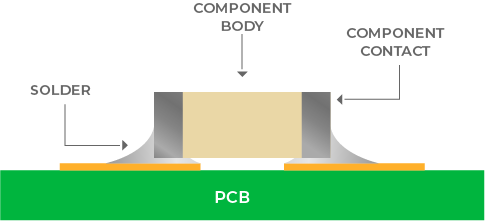

Surface Mount Technology (SMT) refers to the now prevalent method for attaching the various components of a finished printed circuit board (PCB) to the surface of the board (e.g. anchoring the transistors, resistors, capacitors, inductors, transformers, diodes, sensors, and other electronic components to the board). SMT involves mounting components onto the surface of the PCB by soldering them to small copper “pads” which are printed onto the board and are part of the board’s circuitry. Pads thus serve both to attach components to the board and to transmit electricity to and from them. SMT is how most circuit boards are assembled today because the process has been standardized and, for large scale manufacturers, SMT has been mechanized making the assembly of large numbers of boards not only possible, but relatively inexpensive. Over time SMT technology has evolved to permit the use of ever smaller components and circuits in PCBs as well as to allow PCBs to have multiple layers of circuitry.

Advantages and disadvantages of SMT

Advantages:

- Compatible with miniaturized PCB components and circuitry

- Mechanized for inexpensively assembling large quantities of PCBs

- Adapted for use on both sides of PCBs

Disadvantages:

- Forms the weakest physical part of the circuitry of a PCB

- Does not support the use of high levels of electric power

What is Through-hole technology?

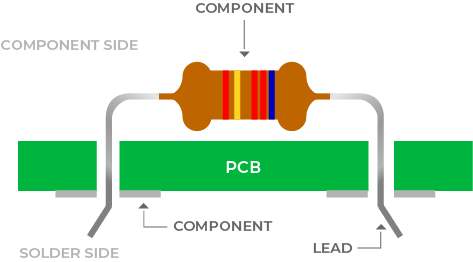

Through-hole technology (THT), as you might imagine, involves the use of holes drilled through a circuit board, a technology that dates back to the 1950s.The holes allow component leads to pass through the board where they are then soldered to pads printed on side of the board opposite to the component.

Advantages and disadvantages of Through-hole technology

Advantages:

- Components are more strongly attached to the PCB than with SMT

- Supports high levels of electric power

- Higher thermal tolerance than SMT

- More established and trusted than SMT for many applications

Disadvantages:

- Relies upon more expensive and complex equipment than SMT resulting in higher cost PCBs

- Slower assembly speed than SMT assembly

Do electronic contract manufacturers prefer one technology to the other?

Both SMT and THT are used and useful technologies. SMT is better suited for certain PCB designs and THT for others. Generally, SMT is preferable for small component, high volume PCB assembly. But for producing physically robust circuitry capable of handling high-powered applications, THT is preferred. Manufacturers of massive numbers of printed circuit boards for use in home computers for example have gravitated to SMT while manufacturers of PCBs for military or aerospace uses will typically prefer THT.

PCB Assembly Express is a full service contract manufacturer located in Oregon. We have extensive experience employing both SMT and THT PCB assembly methods. You can rely on our high precision machinery and rigorous quality control procedures to assemble your printed circuit boards with the technology that best suits your needs. We do prototype PCB assembly as well as larger volume assembly and offer very competitive pricing.

LEAVE A REPLY